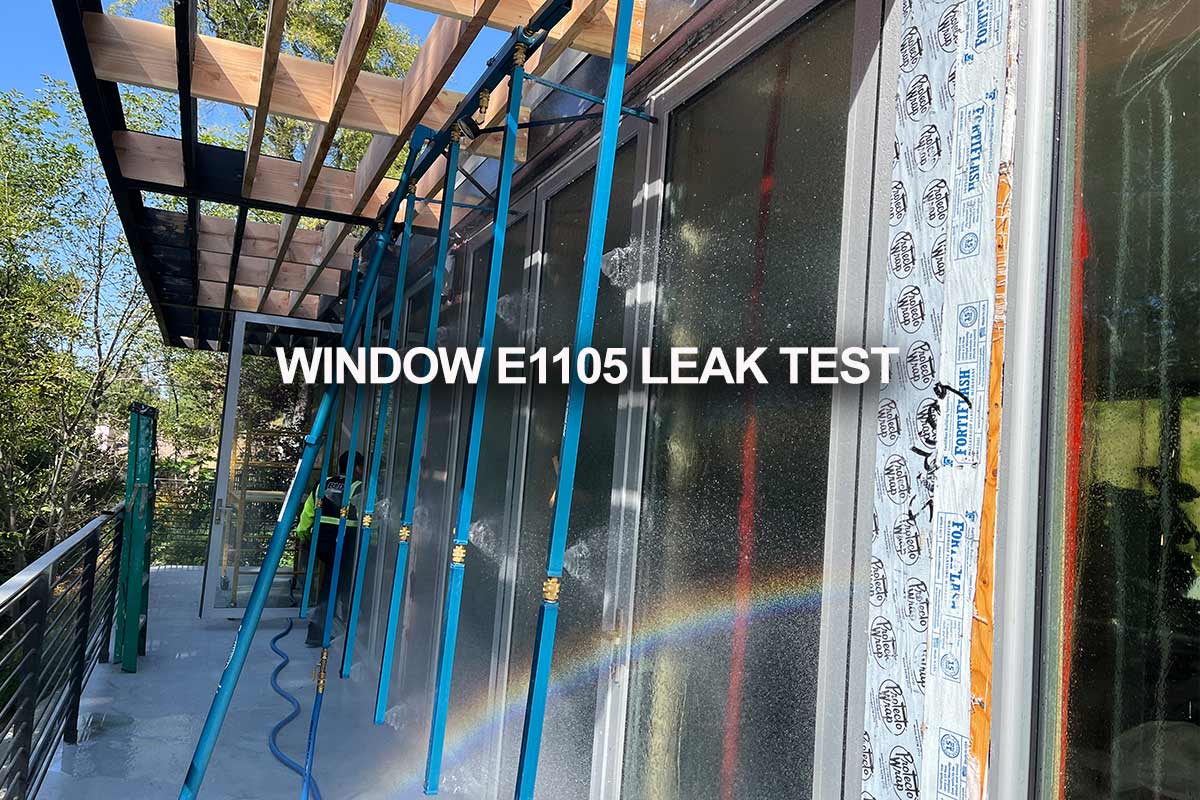

ASTM E 1105 Water Intrusion Test in Las Vegas

In order to evaluate the water penetration resistance of external wall systems, such as windows and doors, ASTM E 1105 is a standard test technique that was created by ASTM International. The test is frequently referred to as the “Uniform Static Air Pressure Difference Method for Water Penetration Testing of Exterior Windows, Skylights, Doors, and Curtain Walls.”

ASTM E 1105’s Key Features:

Objective:

The primary objective of the test is to ascertain whether water can penetrate a building envelope system when it is exposed to a specific air pressure differential.

ASTM E 1105 Setup:

The test is typically conducted under controlled conditions using a test apparatus that replicates environmental pressures and conditions. The assembly that is being tested is subjected to a static air pressure difference and a water discharge.

ASTM E 1105 Procedure:

The test specimen (e.g., a window or wall system) is affixed to a testing frame.

– The specimen’s exterior is uniformly sprayed with water.

– Wind pressure and stack effect are simulated by establishing an air pressure differential between the interior and exterior of the specimen.

– Water infiltration is monitored in the assembly.

Criteria for Success:

The specimen is considered to have passed the test if no water is allowed to enter the interior side through any joints, fissures, or openings under the specified testing conditions.

ASTM E 1105 Applications:

This test is frequently employed in the construction industry to evaluate the performance of building envelope components and guarantee adherence to safety and durability standards. It is imperative for manufacturers and architects to verify that their products can withstand environmental conditions without sustaining water damage.

In essence, ASTM E 1105 is a critical method for assessing the water resistance of building façade systems, thereby ensuring their effective performance in real-world conditions.

Administering the ASTM E 1105 test in Las Vegas

The ASTM E 1105 test assesses the water penetration resistance of external windows, skylights, doors, and curtain walls. This is a general framework for administering the test:

Required Equipment:

Water Supply: A method for providing water to the specimen, usually via a spray nozzle.

Measuring Instrument: For quantifying water pressure and flow rate.

Timer: To monitor the length of the examination.

Test Specimen: The window, skylight, or wall assembly being evaluated.

Testing Protocol: Prepare the Environment: Verify that the testing area is sanitized and that the specimen is installed in accordance with the manufacturer’s specifications.

Choose the Test Specimen: Confirm that the specimen selected for testing accurately represents the assembly under standard field conditions.

Administer Water Pressure: – Employ a calibrated spraying apparatus to deliver water to the specimen at a predetermined pressure. Per ASTM E 1105, water is generally delivered at a pressure of 20 psf (pounds per square foot) or greater, contingent upon the standards.

Timing: – Initiate the timer upon the application of water. Sustain the test conditions for a designated period (often 15 minutes).

Examine the Sample: – Upon completion of the test time, scrutinize the interior surfaces next to the specimen for indications of water infiltration. Record all instances of water infiltration.

Document the Findings: – Record the testing parameters, specimen characteristics, and any detected water infiltration. Submit a detailed report on the findings.

Safety Precautions: – Implement suitable safety protocols concerning the utilization of water and equipment.

– Assess the structural integrity and security of the test specimen prior to commencement.

Consistently consult the most recent edition of ASTM E 1105 for explicit instructions, procedural variances, and comprehensive requirements. If you have any inquiries or require assistance with particular aspects, do not hesitate to ask!